Underground Injection Control (UIC) Permitting in the Delaware Basin

As oil production in the Permian Basin continues to grow, so does the challenge of wastewater management in west Texas. Areas in the Permian Basin have high water cuts, meaning that operators produce relatively large amounts of water in addition to oil (as many as 12 barrels of water for each barrel of oil in some places). Since most of the produced water must be transported and disposed of, usually in a saltwater disposal well (SWD), these high water volumes can significantly increase production costs per barrel of oil produced. Within the Permian Basin, the Delaware Basin sub-area is front and center for wastewater management concerns. Not only do many wells there produce some of the highest water cuts in the Permian Basin, but specific counties in the basin are experiencing increased seismicity. While the science of seismicity and its relationship to water disposal is still a topic of research at institutions like the Texas Bureau of Economic Geology. Concerns related to seismicity have added to an examination of the saltwater disposal industry, as well as other factors related to subsurface injection. In particular, the Railroad Commission of Texas (RRC) has increased its scrutiny when evaluating applications for SWDs. As continued growth in saltwater disposal capacity is critical to absorb incremental produced water associated with growing oil production. It is important to understand how this increased scrutiny affects the process and timeline of applying for new injection wells.

A significant increase in UIC applications

In 2018, more than 400 permit applications for underground injection wells were submitted to the RRC; over 300 of which were for brand new wells. Although some of these wells are used for enhanced oil recovery (EOR), most of them are purely for disposal. As of May 15, there have already been over 220 permit applications for wells submitted in 2019, of which, 200 are for new wells as opposed to amendments to existing permits. This is a 150% increase in frequency of submitted applications (YTD) as compared to 2018. Most of the submitted permit applications fall in Reeves County, with 160 new well applications in all of 2018 and just over 80 as of May 15, 2019 alone.

As a result of the increase in permit applications, the RRC has also ramped up the number of permits approved. In the entirety of 2018, around 200 permit applications were approved, 83% of them for new wells. As of May 15, 2019, almost 160 applications have already been approved, with approximately 75% of them for new wells. This is a greater than 200% increase in permit application approval rate since last year. If the rate of application approvals is constant for the remainder of 2019, more than 400 permit applications will be approved by theend of the year.

The number of days to receive an approved application

Currently, on average, it takes about 140 days for a new application to be approved (measured from the day it is received and stamped by the RRC to the day a permit is signed). Every application is unique, depending on location and several other factors, the time it takes to review and approve an application varies. In 2018, the longest duration for a permit to be approved was approximately 1.5 years. Approvals granted in 2019 indicate that the process is taking longer, and some of the recently approved permits took nearly two years to navigate the process. So far this year, permit approvals in Reeves County tend to entail the longest approval process. Permit applications in Loving County have also started to see extended timelines in the approval process, a contrast to 2018, when Loving County had some of the shortest periods of elapsed time between the initial stamp date and the approved permit date. In other counties, such as Ward and Culberson Counties, applications may take as little as two weeks to be approved. Not only does location play an integral role in permit approval, but so do other factors such as letters of protest, subsequent hearings, and requests for additional data from the RRC.

Requests for additional data (RADLTRs)

After the original submission of a permit application is reviewed, the RRC will allow two additional opportunities for review before the application is denied. It is often the case that the RRC needs additional information, or that the original application was submitted with errors or omissions. In many of these cases, the RRC refers the application back to the applicant with a Request for Additional Data (commonly known as a RADLTR). The number of requests for additional data has significantly increased in the last year, particularly in the Delaware Basin. When comparing the permit applications in the Delaware Basin to the Central Basin Platform over the last six months, roughly 68% of the permit applications are within the Delaware Basin, and approximately 75% of the issued RADLTRs were for Delaware Basin UIC applications.

According to B3 and the RRC data, the RRC has also increased its requests for additional data for UIC permit applications in Reeves County. In particular, RADLTRs seeking more seismicity related information are prevalent there, as Reeve’s County remains a hotspot for new SWDs. The primary reason for RADLTRs is to ensure that injection wells will not cause subsurface issues, such as damage to geological structures caused by pressure exceeding the fracture gradient. These requests include items such as isopach maps, cross sections, fault-slip potential tests, bottom-hole pressure tests, step-rate tests, injectivity assessments and other items. These tests are used to prove that the well will be able to handle the requested capacity. If an applicant is unable to prove that the well can handle the requested injectivity rate and pressure, then it will be requested to decrease one or both to a value that satisfies the RRC’s standards (located at https://www.rrc.state.tx.us/oil-and-gas/publications-and-notices/manuals/injection-disposal-well-manual/summary-of-standards-and-procedures/ under “Summary of Standards and Procedures”). These requests for additional data are common for recently submitted permit applications and can cause significant delay in the approval process. For example, a recently approved permit in Reeves County was submitted in May of 2018 and was not approved until May of 2019. The permit application had a series of RADLTRs that spanned over an 8 month period and requested a multitude of additional tests.

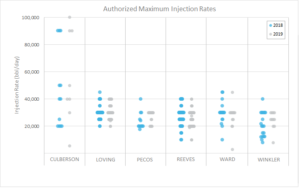

Injectivity capacity limitations

Along with those in Reeves County, other counties are also seeing significant requests for additional information for underground injection wells, with Loving County and Pecos County coming in second and third, respectively; and Ward County follows not too far behind. While these counties receive the largest number of permit applications, they are not the counties with the largest approved injection rates and pressures. Culberson County ranks first for maximum requested and approved volumes so far in 2019, with wells that have been approved for up to 100,000 bbl/day and over 7,000 psig in non-productive zones. This is a shift from 2018, when Reeves County had the highest authorized pressures (over 7,000 psig). In 2019, no permits have been authorized in Reeves County with maximum pressure capacities over 7,000 psig. Importantly, many of the applications that have requested high injection pressures and volumes have had those capacities significantly reduced from the original requested values. Some of the most recently approved wells in May 2019 have had capacity reductions of 33% for injection rates and 50% for injection pressures from the originally applied for rates. These kinds of limitations can reduce the total volume of a new SWD, which adds uncertainty to future disposal needs.

Another major factor in approved injectivity rates and pressures is the determination between injection into a formation productive of oil or gas or a formation not productive of oil and gas. RRC handles permitting for SWDs that inject into productive zones as a completely different application than those that inject into non-productive zones. In 2018 and so far in 2019, wells injecting into productive zones have only been approved for maximum rates of up to 45,000 bbl/day and maximum injection pressures of around 3,000 psig. Recently, approved permit applications for wells in productive zones have seen a 10,000 bbl/day decrease in injection rates from what they applied for. Those applying for wells in non-productive zones are being approved for almost double the capacity as the wells in productive zones (up to 100,00 bbl/day and 7,000+ psig). However, although these pressures are high, they are not as high as some had originally requested in their initial applications. Operators have requested over 8,500 psig is some areas, over 1,000 psig more than any recently approved maximum pressures.

Long term strategic planning

Between the complexity of seismicity, protests, and requests for additional data, permitting new SWDs in the Permian Basin is not an easy task. When an applicant successfully acquires a permit, it is generally not without significant supplemental information and often, the applicant does not obtain the injection rates and pressures they originally applied for. Operators must plan in advanced in order to claim enough disposal capacity. Planning and executing a SWD in the Permian Basin, and more specifically, in the Delaware Basin, requires advanced preparation and knowledge of the daily changing activity in the area.

If you are an operator or midstream company, it is critical to understand where nearby operators are considering disposal wells, the timeframe to permit new injection wells, conditions under which a permit is successfully approved, and much more. B3 Insight publishes a UIC Permit Application Monitor report every two weeks to subscribers which covers the Delaware Basin and Central Basin Platform. This report provides up-to-date insight on UIC Permit Applications for the previous four weeks.

Contact [email protected] or call 720.664.8517 if you are interested in receiving this report.